Glazing Tools for Glass Replacement: Step-by-Step Equipment Guide

Glazing Tools for Glass Replacement: Step-by-Step Equipment Guide. Replacing a pane in a window or door requires the right tools, accurate measurement and ...

Glazing Tools for Glass Replacement: Step-by-Step Equipment Guide. Replacing a pane in a window or door requires the right tools, accurate measurement and safe technique. Whether you are a tradesperson fitting sealed units daily or a homeowner carrying out a one-off repair, the correct glazing tools will improve finish quality, reduce risk and save time.

Essential personal protective equipment

Safety is the first priority when working with glass. Always use suitable PPE before starting work:

- Safety glasses or goggles rated to EN166 to protect against shards and dust

- Cut-resistant gloves for handling glass and sharp tools; leather gloves for heavier handling

- Steel-toe boots on site or sturdy footwear at home

- Long sleeves and eye protection when using power tools

- Dust mask if grinding or removing hardened putty

Basic glazing tools every job needs

These are the everyday tools for most repairs and replacements, suitable for timber, PVCu and aluminium frames:

- Glazing knife and flexible fill knife for applying and striking putty or sealant

- Glazing chisel and cold chisel for raking out old putty or beads

- Putty raker or rasp for cleaning rebates

- Glass suction cups for lifting panes safely; use two for panes over 6–8 kg or large sizes

- Glazier's points or retaining clips for timber frames; stainless steel clips for exterior use

- Setting blocks and packers to correctly support the glass and maintain clearance

- Glazing wedges and plastic shims to centralise the glass and set even gaps

- Sealant gun (skeleton or pneumatic) for silicone or PU sealant; choose one with smooth action

- Sharp tape measure and spirit level; a small combination square helps check rebates and mitres

Tools for sealed units and double glazing

Fitting insulated glass units (IGUs) needs some additional attention and equipment:

- Edge spacer and setting block kit: place at quarter points to support unit and prevent glass bowing

- Adhesive glazing tape or pre-formed gaskets for PVCu and aluminium frames; ensure correct width and durometer

- Suction lifters rated for IGUs; larger panes require multi-suction systems

- Isolation and protection blocks to avoid compressing sealant or damaging spacers

- Cut-resistant gloves with a good grip; IGUs can be heavy and awkward

Specialist tools for traditional joinery and conservation

Working with old timber sashes or heritage windows requires different methods and tools:

- Decorators’ heat gun for softening old putty; use low heat and avoid direct flame

- Putty combs and shaping tools for a traditional finish

- Sash crampons and small pry bars for careful bead removal without damaging timber

- Traditional glazing points and linseed oil putty for period repairs

- Fine rasps and chisels for precise rebate cleaning

Step-by-step equipment use: practical workflow

The following steps outline the typical sequence and which tools to use at each stage. Adjust methods for the type of frame and glass involved.

- Preparation: Clear the work area and lay dust sheets. Remove loose paint and dirt with a brush. Put on PPE.

- Remove glazing beads or stop beads: Use a thin pry bar, sash crampon or careful twisting with a putty knife; protect the bead with a block of timber when levering out. Keep fixings for re-use when possible.

- Rake out old putty or remove the broken pane: Cut old putty back with a glazing chisel or putty raker. For tough putty, warm gently with a heat gun; for sealed units, do not apply heat to glazing seals. Remove all fragments and clean the rebate down to sound material.

- Measure and order replacement glass or IGU: Measure the clear opening and subtract appropriate edge clearance: typically 3 mm in timber rebates and 3–4 mm for PVCu depending on manufacturer guidance. For IGUs, follow supplier tolerances and record bead depth and sightlines.

- Pre-fit setting blocks and shims: Place blocks at quarter points on the sill to support the unit. Use glazing wedges to centre the glass so there is uniform reveal around the perimeter.

- Set the glass: Use suction cups for lifting. Gently lower into position and check for level and squareness with a spirit level. Adjust with wedges and packers as required.

- Secure the glass: Install glazing points or clips: place points approximately every 150–200 mm in timber frames. For PVCu and aluminium fit gasket or adhesive glazing tape per manufacturer instructions.

- Seal or putty: For external sealing, use a neutral-cure silicone compatible with glass and frame materials. For traditional timber windows, apply linseed oil putty and strike neatly with a glazing knife. Allow sealant or putty to cure before painting or exposing to the elements.

- Finish: Refit beads using new brads or screws if necessary. Clean the glass with a non-abrasive cleaner and remove any remaining putty or sealant residue with a plastic scraper.

Practical trade tips and common pitfalls

- Always double-check the rebate depth before ordering IGUs; incorrect depth leads to poor support and premature failure.

- Use stainless fixings for external beads to avoid corrosion staining.

- Avoid over-tightening gaskets in PVCu frames; this can distort IGUs or impede thermal movement.

- Keep a small selection of spare setting blocks and a roll of glazing tape on the van: they are inexpensive and often needed on site.

- When replacing sealed units, inspect the spacer edge and desiccant: damaged or fogged units should be replaced rather than resealed.

- For sash windows, mark bead locations before removal to ensure accurate refitting and maintain original weathering profiles.

When to call a professional

Small single-pane replacements in easily accessible frames can be DIY for competent homeowners. Call a glazing specialist for:

- Large or heavy panes where lifting equipment is required

- Structural glazing or bonded IGUs

- Heritage-listed windows requiring conservation techniques

- Significant frame rot or movement that affects sealing and support

- Complex aluminium or curtain wall systems

Recommended Products

Based on this article, you may find these products helpful:

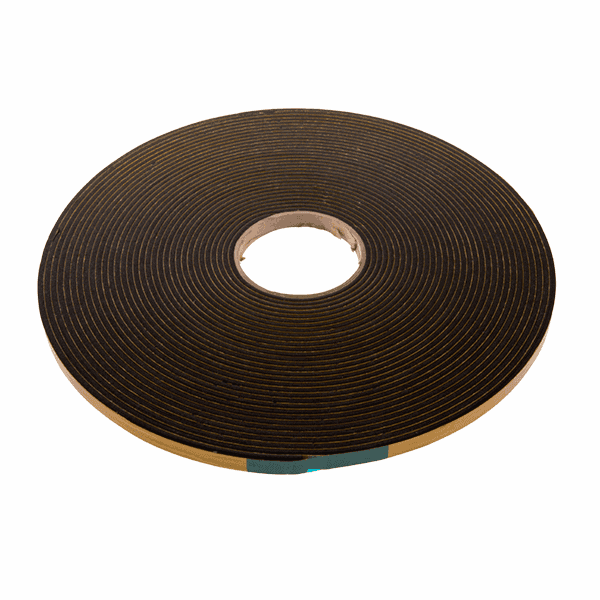

- Structural Glazing Tape - 20mm

- Security Glazing Tape

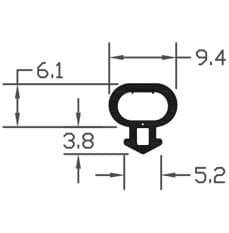

- B003 Bubble Gasket

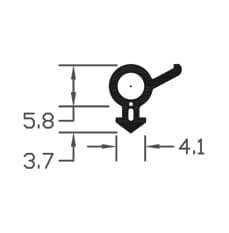

- B004 Bubble Gasket

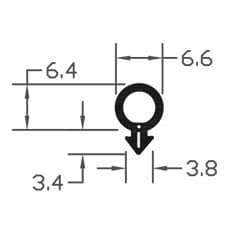

- B007 Bubble Gasket

Conclusion and next steps

Using the right glazing tools and following a methodical sequence will produce durable, weatherproof results. For trade professionals, investing in quality suction cups, setting blocks and a reliable sealant gun pays dividends in speed and finish. Homeowners should check frame condition and order the correct sized pane or IGU before starting work.

Next steps: gather the tools listed here, measure the opening carefully, and consult the window or frame manufacturer where gaskets or tape compatibility is critical. For specialist supplies and trade-grade glazing tools, see our double glazing resources: /guides/double-glazing-supplies.