How to Lubricate and Maintain Your Espagnolette Mechanism

How to Lubricate and Maintain Your Espagnolette Mechanism Why regular maintenance of an espagnolette matters Espagnolette mechanisms control the locking po...

How to Lubricate and Maintain Your Espagnolette Mechanism

Why regular maintenance of an espagnolette matters

Espagnolette mechanisms control the locking points on casement windows and some doors; they consist of a gearbox, a spindle, rods or cams and several keeps and strikes. Regular lubrication keeps the mechanism operating smoothly, reduces wear on gears and keeps, and prevents issues such as sagging sashes, jammed handles and draughts. Proper servicing also prolongs the life of the window hardware and helps maintain security and weather performance.

Tools and materials you will need

- Silicone or PTFE spray lubricant: suitable for uPVC, aluminium and painted timber; use a dry PTFE for long-lasting, non-greasy protection

- Light machine oil: for steel pivots, linkages and gearbox spindles if required

- White lithium grease: for heavier gear assemblies on external doors and heavy frames

- Household detergent, warm water and a soft cloth: to remove grime before lubrication

- Small brush and cotton buds: for cleaning tight areas

- Screwdrivers and hex keys: to remove handles and access plates

- PPE: gloves and eye protection when spraying lubricant

- Drop cloth or masking tape: to protect glass and frame finishes

Inspection and preparation

Before applying any lubricant, inspect the espagnolette visually and feel for problem areas. Operate the handle slowly and note any sticking points, excessive play or unusual noises. Check for loose fixings, corroded components and damage to keeps.

- Open the sash and support it securely; for heavy doors get assistance so the sash does not move while you work.

- Remove the handle and any cover plates to expose the gearbox and the rod or cam if necessary; keep screws in a small container.

- Clean visible dirt and old grease with warm soapy water and a soft brush; avoid abrasive cleaners on painted or powder-coated surfaces.

Step-by-step lubrication process

Use the following sequence for a systematic service of most espagnolette systems:

- Apply lubricant to the gearbox spindle and the handle spindle: a couple of short bursts of PTFE or a drop of light machine oil will reduce friction at the primary pivot.

- Lubricate the locking cams and rollers: spray PTFE into the recesses where cams and rollers engage the keeps. This will help them run smoothly and prevent squeaks.

- Treat the length of the espagnolette rod or strip: move the handle to expose different sections and apply a light film of lubricant along the moving parts; wipe away excess to prevent attracting dust.

- Spray keeps and strikes: a small amount of dry lubricant on keeper plates ensures good contact without smearing onto seals; avoid heavy greases on faceplate areas where seals compress.

- Cycle the mechanism: operate the handle through its full travel at least 10 times to work the lubricant into cam faces, rollers and gears; reapply sparingly to any remaining dry spots.

- Wipe down: remove overspray from glass and frames using a soft cloth and mild detergent if needed.

Product selection and what to avoid

Choose a lubricant appropriate to the material and environment: PTFE and silicone sprays are excellent for uPVC and aluminium because they do not attract dust. White lithium grease works well for heavier duty steel components on external doors. Light machine oil can be used for pivots and fine linkages.

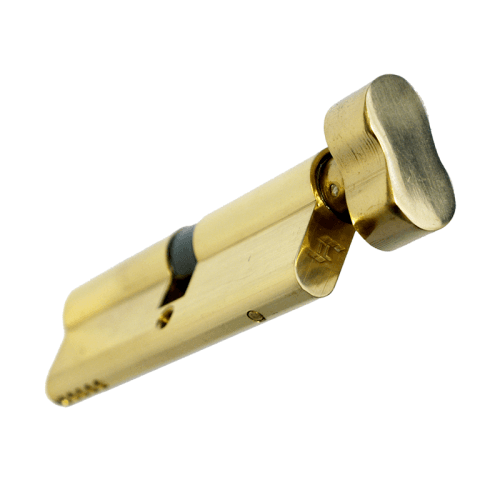

Avoid using penetrating solvents such as WD-40 as your long-term lubricant: they are useful for displacing moisture but not for sustained lubrication. Do not use thick automotive greases on cam and keeper interfaces where seal compression and precise contact are required; thick grease can cause sticking and attract grit. For euro cylinders and key locks, use a dedicated lock lubricant such as graphite powder or a dry PTFE lock spray; do not pour oil into key cylinders.

Troubleshooting common espagnolette problems

- Stiff or jammed handle: check for misaligned keeps or bent rods; loosening and realigning the keeps can restore smooth operation. If the gearbox is seized, it may need replacement rather than just lubrication.

- Sluggish locking points: apply PTFE to the rollers and cams, then cycle the handle. If wear has occurred on cam faces or rollers, replacement components are preferable to excessive lubrication.

- Excessive play in handle: tighten spindle grub screws or handle fixings; if the gearbox shows internal wear, fitting a new espagnolette mechanism may be necessary.

- Corrosion on metal parts: remove surface rust with a wire brush, treat with a rust inhibitor and lubricate; heavily corroded strips should be replaced to maintain security.

Trade tips and advanced maintenance advice

- For trade professionals: keep a service kit with PTFE spray, lithium grease and replacement rollers and plastic gears for common espagnolette brands; parts often wear before the whole mechanism needs replacing.

- Adjust keeps rather than applying excessive lubricant: poor alignment causes premature wear; small adjustments to the keeper positions can eliminate sticking without more frequent servicing.

- Document the service: note date, products used and any parts replaced; this helps when scheduling future maintenance and when advising clients.

- Coastal properties require more frequent servicing due to salt corrosion: inspect and lubricate every 3 to 6 months rather than annually.

Maintenance schedule recommendations

For typical UK domestic windows and doors, check and lubricate espagnolette mechanisms every 12 months. For high-use or coastal locations, reduce the interval to 3 to 6 months. Perform a visual check after severe weather and act promptly on any signs of corrosion or misalignment.

Recommended Products

Based on this article, you may find these products helpful:

- TL Thumb Turn Euro Cylinder

- Ultion Plus TS007 3* Kitemarked Euro Key & Turn Cylinder

- ERAB Espagnolette Window Lock Universal Lock Replacement

- Avocet Slimline Offset Window Espag

- In-Line Window Mechanism

Conclusion and next steps

Regular inspection, correct cleaning and the right lubricants will keep your espagnolette mechanism functioning reliably and extend the life of your window and door hardware. If you encounter seized gearboxes, bent rods or significant corrosion, replacement parts or a trade repair will be the safer option.

For more detailed technical information and component diagrams consult our espagnolette guide. If you need replacement parts or professional support, contact Window Hardware Store for trade-grade lubricants and components supplied across the UK.

Related articles

Window Gearbox Maintenance: Keeping Your Locks Working Smoothly

Window Gearbox Maintenance: Keeping Your Locks Working Smoothly A well maintained window gearbox keeps casement and tilt-and-turn windows operating smoothl...

Troubleshooting Shootbolt Problems: A Window Fitter's Guide

Troubleshooting Shootbolt Problems: A Window Fitter's Guide Shootbolts are a small but vital component in many modern window and patio door locking systems...

What Is a Shootbolt Lock? Complete Guide to Window Security

What Is a Shootbolt Lock? Complete Guide to Window Security What is a shootbolt? A shootbolt is a mechanical locking element commonly used in windows and d...