How to Use Glazing Tools: A Beginner's Guide

How to Use Glazing Tools: A Beginner's Guide. Whether you are a UK homeowner replacing a cracked pane or a trade professional refreshing your kit, understa...

How to Use Glazing Tools: A Beginner's Guide. Whether you are a UK homeowner replacing a cracked pane or a trade professional refreshing your kit, understanding how to use glazing tools correctly will save time, money and reduce the risk of mistakes.

Why the right glazing tools matter

Good glazing work depends on precision, the correct sequence and suitable materials. Using the right tools ensures a weatherproof seal, correct support for the glass and a neat finish. For traditional timber frames the approach differs from uPVC or aluminium systems, and double-glazed sealed units have different requirements to single-pane repairs. Choosing appropriate tools and techniques avoids drafts, water ingress and premature failure.

Essential glazing tools and consumables

- Glazing knife: for cutting and tooling putty; get both stiff and flexible blades.

- Putty chisel and glazing paddle: for removing old putty and shaping fresh putty.

- Glass cutter and running pliers: for cutting float and annealed glass.

- Suction cups and glass carriers: for safe lifting of large panes.

- Setting blocks and packers: to support the glass and set correct sightlines.

- Bead removal tool or small pry bar: for uPVC and timber glazing beading.

- Sealant gun and compatible sealants: silicone or mastic suitable for window use.

- Gasket rollers and trim tools: for compressible seals on modern units.

- Tape measure, spirit level and square: for accurate positioning and alignment.

- Personal protective equipment: cut-resistant gloves, safety glasses and work boots.

Preparing to glaze: checks and setup

Start by identifying the window type: single glazed with putty, uPVC with beads, or double-glazed sealed units. For sealed units remember that the sealed air gap makes repairs different and often means replacing the whole unit rather than reglazing. Remove loose putty or beads carefully; use a putty chisel or bead removal tool to avoid damaging timber or plastic. Clean the rebate and sightline, remove old glazing compound, dust and grease. Check frame condition: rot in timber or warped frames must be repaired before glazing.

Step-by-step: putting in a single pane (traditional putty glazing)

- Measure the opening carefully: subtract the recommended gap for expansion on all sides. Trade practice is to allow a small uniform gap so the glass is not tightly packed.

- Fit two setting blocks at the base of the rebate, positioned roughly 10–15mm in from each corner; these support the glass and transfer weight.

- Place thin packers at the sides to centralise the pane and control gaps; ensure the glass sits square and level.

- Apply a fillet of glazing compound or putty to the rebate using the glazing knife: press a continuous bead so the glass will sit onto the putty.

- Offer the glass into position and press gently onto the putty so it supports the pane fully on the setting blocks; remove excess putty with the knife.

- Tool the external putty to a neat slope with the putty knife so water runs away from the bead and does not pool.

- Once the putty skins or cures, reinstall or cut new beading if needed and prime any exposed timber with an appropriate preservative and paint.

Reglazing uPVC and modern sealed units: key differences

uPVC frames typically use removable glazing beads clipped into place. To replace glass remove the appropriate beads with a bead removal tool; keep smaller beads safe as they can be fragile. Modern sealed units are factory-made and usually require replacement of the whole unit if the seal fails or the glass is damaged. Use setting blocks recommended by the window manufacturer and avoid bedding sealed units in soft putty: use polyurethane or neutral cure silicone specified for sealed units and follow the manufacturer’s instructions for edge support and compression.

Practical trade tips and common pitfalls

- Always use setting blocks at the bottom edge; failing to set the unit properly can lead to stress and cracking.

- When cutting glass score once firmly and snap with running pliers; repeated scoring creates irregular breaks.

- For large panes use suction lifters and work with a helper: lifting glass solo increases risk of breakage and injury.

- Avoid using acidic silicones against timber or painted surfaces; choose neutral cure products where compatibility matters.

- Ensure external putty or sealant slopes outwards to shed water; a flat or inward slope invites moisture problems.

- For door panels and low-level glazing check safety glass requirements: toughened or laminated glass may be required by building regulations.

Safety, maintenance and tool care

Wear cut-resistant gloves and eye protection whenever handling glass. Dispose of broken glass safely in rigid containers. Keep glazing knives and cutters clean and sharp: a blunt tool is hazardous and gives poor results. For putty work, store traditional linseed oil-putty away from heat and follow COSHH guidance for primers and solvents. Regularly check packers and setting blocks for compression over time and replace if necessary; even correctly glazed units should be inspected periodically for seal failure or deteriorating seals.

When to call a professional

Homeowners can tackle small pane replacements in timber windows or swapping a broken pane in an existing frame if they feel confident. However call a professional glazier for large or high-level panes; sealed unit failures; laminated or toughened glass replacements; structural glazing; or where regulatory compliance such as safety glazing or fire-rated units is involved. Trade professionals should follow manufacturer guidance for proprietary systems and document work for warranty purposes.

Recommended Products

Based on this article, you may find these products helpful:

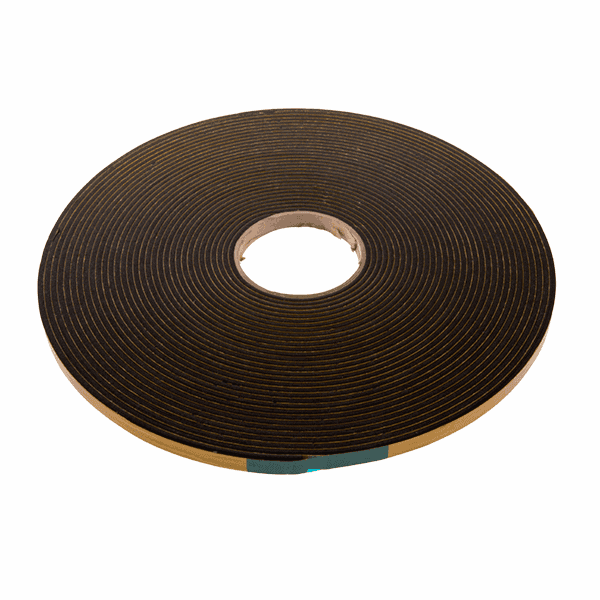

- Structural Glazing Tape - 20mm

- Security Glazing Tape

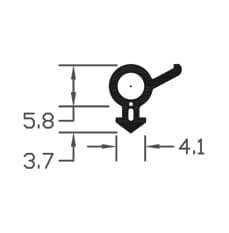

- B003 Bubble Gasket

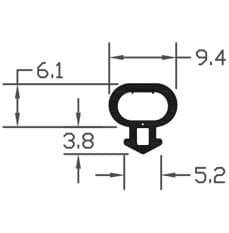

- B004 Bubble Gasket

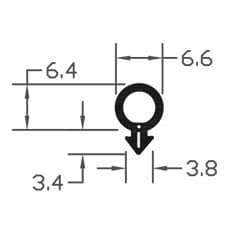

- B007 Bubble Gasket

Conclusion and next steps

Understanding how to use glazing tools well makes glazing repairs and replacements safer and longer lasting. Focus on correct preparation, appropriate materials for the window type, and good support for the glass. For further product choices and detailed supplies consult our double glazing supplies hub at /guides/double-glazing-supplies. If you are unsure about a specific repair or a sealed unit, contact a qualified glazier or call our trade support for advice.