Professional vs Budget Glazing Tools: Is the Upgrade Worth It?

Professional vs Budget Glazing Tools: Is the Upgrade Worth It? Choosing the right glazing tools affects quality, speed and safety for window and door insta...

Professional vs Budget Glazing Tools: Is the Upgrade Worth It?

Choosing the right glazing tools affects quality, speed and safety for window and door installations. Whether you are a trade glazing contractor, an installer for a small business, or a confident DIY homeowner, the decision to pay more for professional-grade tools or save with budget items should be based on the job frequency, required tolerances and the consequences of a poor finish. This article compares the two approaches and gives practical trade and DIY advice to help you decide.

What distinguishes professional from budget glazing tools

At a fundamental level the difference comes down to materials, tolerances, ergonomics and serviceability. Professional glazing tools are built for repeated use: hardened steel blades, corrosion-resistant bodies, sealed bearings and replaceable parts. Budget tools are often utilitarian; they will do the job for occasional repairs but wear faster and may deliver less consistent results.

Key attributes that separate professional tools from cheap alternatives include:

- Material quality: stainless or heat-treated steel, anodised aluminium, high-grade plastics

- Precision: tight manufacturing tolerances for consistent cuts and spacing

- Ergonomics: comfortable grips and reduced vibration for less fatigue

- Serviceability: replaceable cartridges, blades and parts rather than whole-unit replacement

- Warranty and support: parts availability and trade support from manufacturers

Key tool categories and where upgrades matter

Not all glazing tools benefit equally from an upgrade. Here are categories with practical notes on when professional tools are worth the investment:

- Glass handling and lifting: Suction cups and vacuum lifters: upgrade if you handle large or heavy units regularly; better suction, higher load ratings and redundancy increase safety.

- Cutting and scoring: Glass cutters and running pliers: professional cutters keep a sharper, more consistent score line; budget cutters are fine for occasional small jobs.

- Sealing and sealant application: Cordless caulking guns: trade-grade guns provide smoother delivery and adjustable pressure; for a single window, a manual gun is usually sufficient.

- Beading and bedding tools: Rubber hammers, beading shavers, glazing shims and wedges: professional tools reduce damage to frames and give a cleaner finish, particularly on premium aluminium or timber frames.

- Setting blocks and packers: These are inexpensive but accurate, so invest in a good set with known dimensions; they are essential for correct glazing unit support.

- Multi-tools and grinders: If you are trimming frames or altering sills frequently, a quality oscillating tool or angle grinder will save hours and produce better edges.

When professional glazing tools are worth the cost

Tradespeople and fitters will see the greatest return from upgrading. Time saved on each job reduces labour costs; higher accuracy lowers the risk of failed seals and customer call-backs. Specific benefits include:

- Faster working times: smoother tool operation shortens install time and increases daily throughput

- Better finishes: tighter tolerances produce consistent sightlines and neat bead runs

- Reduced rework: robust tools lead to fewer damaged frames or glass breaks

- Safety: tools designed for heavy use include features to reduce slips and hardware failures

For trade users the purchase decision is often simple: if a tool is used daily, buying professional grade usually pays back within months through time saved and fewer defects.

When budget tools are sufficient: DIY and occasional work

Homeowners replacing a single pane or fitting new internal glazing beads may not need professional kit. Budget glazing tools can be adequate for small jobs where precision tolerances and high throughput are not essential. Practical tips for DIYers:

- Start with the essentials: good-quality safety glasses, gloves, a decent putty knife, a basic silicone gun and a set of setting blocks

- Hire specialised items: for heavy or awkward glass use hire suction lifters or a vacuum lifter rather than buying one

- Practice on a scrap piece of glass to learn scoring and snapping technique before tackling an actual unit

- Follow manufacturer guidance for sealants and tapes; poor compatibility is a common cause of failed seals

Maintenance, replacement parts and total cost of ownership

One reason professional tools are cost-effective is the easy availability of replacement parts: blades, seals, cartridges and batteries. Budget tools are often disposable; once the one-piece plastic mechanism fails you must replace the whole item. Consider the total cost over three years rather than the upfront cost.

Maintenance tips that extend tool life:

- Clean sealant residue off guns immediately after use to prevent gumming up

- Keep blades and cutters oiled and stored dry to avoid rust

- Replace worn suction cups and seals on lifters before they fail

- Calibrate torque settings on powered tools periodically for consistent performance

Safety and regulatory considerations

Glazing work carries risk from glass breakage and solvent fumes. Professional tools often include safety features: dual-suction lifter redundancy, blade guards, and controlled extrusion on sealant guns. For traders working to building regulations and warranty conditions it is important to use tools and materials compliant with industry standards; incorrect sealing or unsupported units can invalidate manufacturers' guarantees.

Practical purchasing advice

If you are unsure what to buy, follow this approach:

- List tasks you do regularly and the consequences of failures: more frequent tasks and higher-risk jobs justify better tools

- Buy professional for items you rely on daily, rent or use budget for occasional use

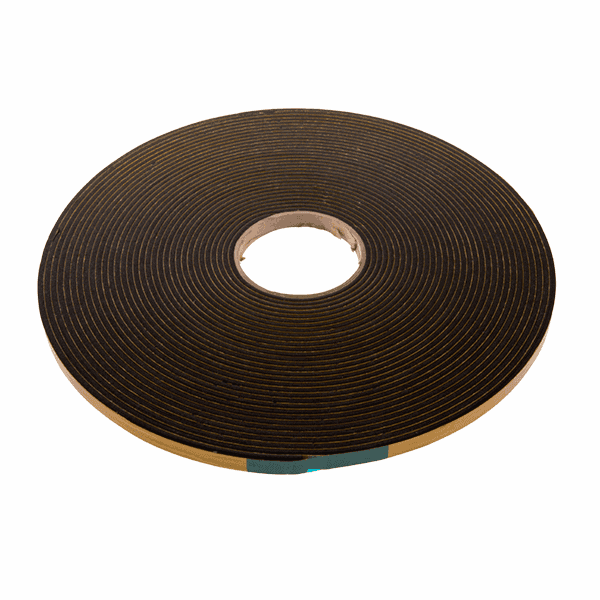

- Purchase consumables and spare parts from reputable suppliers; compatibility matters for sealants and glazing tapes

- Train on technique; even the best glazing tools need skilled use to deliver the best result

For more product-specific information and a wider selection of double-glazing supplies, see our pillar resource at: /guides/double-glazing-supplies.

Recommended Products

Based on this article, you may find these products helpful:

- Structural Glazing Tape - 20mm

- Security Glazing Tape

- In-Line Window Mechanism

- Offset Window Mechanism

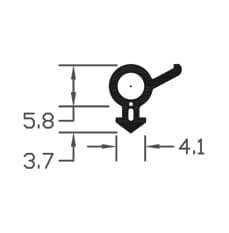

- B003 Bubble Gasket

Conclusion and next steps

Upgrading to professional glazing tools is worth it if you work on glazing installations regularly, handle large or premium units, or cannot afford rework. For occasional DIY repairs, a pragmatic combination of budget essentials plus hired professional equipment will usually suffice. Next steps: assess how often you will use the tool, calculate expected time savings and maintenance costs, and consider hiring high-cost items for single tasks. If you are a tradesperson wanting recommendations for specific tool sets, contact a specialist supplier or request a trade quotation to compare long-term costs and warranties.