Seasonal Double Glazing Supplies: Preparing for Winter Window Maintenance

Seasonal preparation keeps windows performing through the cold months and reduces costly call-outs. Whether you are a trade professional stocking up for wi...

Seasonal preparation keeps windows performing through the cold months and reduces costly call-outs. Whether you are a trade professional stocking up for winter contracts or a homeowner tackling routine maintenance, a clear plan and the right double glazing supplies will prevent draughts, condensation damage and security issues. This post covers practical items to have on hand, tasks to prioritise and safe techniques you can use now to safeguard windows and doors over winter.

Why winter window maintenance matters

Colder weather exposes weaknesses in frames and sealed units. Temperature differentials increase condensation risk and can reveal failing seals. Water ingress freezes and expands, worsening gaps and causing timber to swell or uPVC to distort. For tradespeople, proactively offering seasonal checks increases customer satisfaction and reduces repeat visits. For homeowners, a small amount of maintenance now avoids heat loss and higher energy bills.

Essential double glazing supplies to stock

- Replacement sealed units: measure accurately and order warm-edge spacers and argon fill where required; failed units showing permanent misting need remaking rather than repair.

- EPDM and TPE compression seals: compatible with uPVC, aluminium and timber frames; stock common profile sizes and colour options.

- Brush and pile weatherstrips: for sash windows and sliding doors; these reduce draughts around moving parts.

- Silicone and polyurethane sealants: neutral-cure silicone for glazing beads and sanitary applications; PU or hybrid sealants for external masonry and thresholds.

- Glazing beads and gaskets: uPVC and aluminium beads for in-situ bead replacement; glazing gaskets for rebating glass into frames.

- Multipoint lock components: espagnolette gearboxes, keeps and striker plates; locking cylinders and thumbturns for rapid replacement.

- Hinges, friction stays and handles: adjustable e-coated hinges for corrosion resistance and replacement friction stays for casement windows.

- Cleaning and preparatory materials: isopropyl alcohol, cleaners suitable for uPVC, glass suction cups, glazing rakes and padded shims.

- Consumables and safety: foam backer rods, glazing packers, PTFE lubricant, graphite powder for cylinders, and PPE including gloves and eye protection.

Practical trade advice for winter work

Plan stock for lead times: sealed units and bespoke gaskets often have longer turnaround in winter; keep common sizes and hardware components readily available. For fitting sealed units, confirm edge spacers and cavity gases at point of order to meet thermal performance expectations. When replacing gaskets, ensure the frame profile is clean and dry; use compatible adhesives and allow cure times as per manufacturer instructions.

When servicing multipoint locks, check gearbox alignment and striker positions; misalignment is a common cause of hard-to-turn handles in cold conditions. Use manufacturer-recommended lubricant on gearboxes and friction stays; avoid heavy oils that attract dust. For aluminium systems, verify thermal break integrity and inspect screw fixings for corrosion; replace e-coated or stainless fixings where necessary.

DIY maintenance tasks for homeowners

- Clean weep holes: remove leaves and debris from sill weep holes using a fine wire or compressed air to prevent winter water build-up.

- Inspect and replace simple seals: brush seals and foam draught strips can be replaced by a competent DIYer; measure lengths and select matching profiles for a snug fit.

- Lubricate moving parts: apply PTFE spray to hinges and rollers; use graphite powder for locking cylinders to reduce the risk of freezing. Do not over-apply lubricant.

- Re-bed external joints: check and re-seal perimeters with appropriate exterior sealant where mortar or mastic has failed; maintain a neat bead and tool into place for weatherproofing.

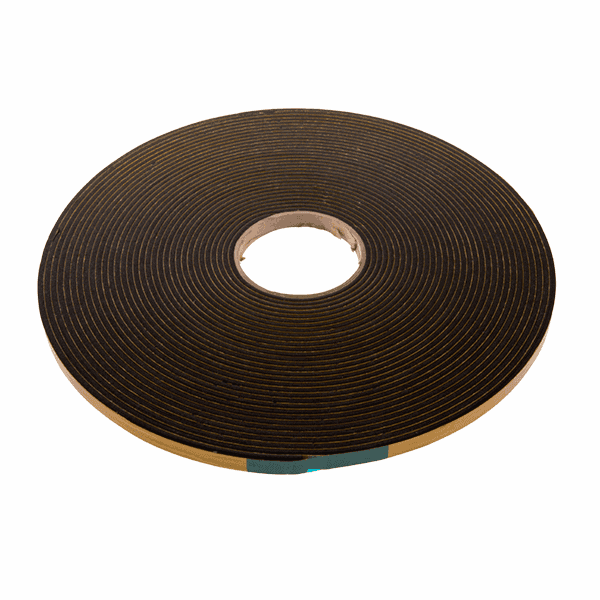

- Temporary fixes: apply edge tape to draughty gaps or fit secondary glazing film as a short-term measure to reduce heat loss; these are low-cost and reversible options.

Troubleshooting common winter problems

Condensation between panes: this indicates a failed sealed unit; replacement is the only reliable remedy. When ordering a replacement, specify warm-edge spacers and argon to improve thermal performance and reduce future misting.

Draughts at joints: if the frame appears sound, check compression seals and glazing beads for wear. Replace EPDM seals or fit brush seals where movement is required. For timber frames, check for shrinkage or rot and address any timber repairs before sealing.

Sticking sashes or swollen timber: allow timber to acclimatise; adjust sash cords and weights or plane out rebounds where appropriate. For uPVC that has distorted slightly, avoid heat guns unless you are trained; professional adjustment or part replacement is safer.

Frozen locks: use a dedicated lock de-icer or apply graphite powder once thawed; avoid using water-based lubricants that can freeze. For persistent freezing, check for water ingress around the cylinder and consider fitting weatherproof covers or replacing with a frost-resistant cylinder.

Tools and safety considerations

Safe handling of glass is essential: use certified glass suction cups and ensure two-person lifts for units over manageable size. Wear cut-resistant gloves and eye protection when working with glass and sealants. When using sealants and solvents, ensure good ventilation and follow COSHH guidance for storage and disposal. For any structural changes or full window replacements that affect the building envelope, check building regulations and use accredited installers when required; this protects both safety and warranty obligations.

Recommended Products

Based on this article, you may find these products helpful:

- Structural Glazing Tape - 20mm

- Security Glazing Tape

- Top Hung Friction Stay - 12"

- ERA Egress (Fire escape) Friction Stay

- TSS Standard Friction Stays – 13mm & 17mm Stack Height

Conclusion and next steps

Preparing now with the right double glazing supplies reduces winter failures, improves thermal efficiency and cuts emergency repair costs. Trade professionals should review stock lists and order key components early; homeowners can complete simple checks, clear weep holes and replace worn seals. For detailed product choices and technical data sheets, visit our pillar resource at /guides/double-glazing-supplies or contact Window Hardware Store for advice on specific systems and compatible parts.