uPVC Window Parts Quality: How to Spot Cheap Imitations

uPVC Window Parts Quality: How to Spot Cheap Imitations Whether you are a trade professional fitting multiple frames a week or a homeowner replacing a faul...

uPVC Window Parts Quality: How to Spot Cheap Imitations

Whether you are a trade professional fitting multiple frames a week or a homeowner replacing a faulty handle, selecting genuine, well-made uPVC window parts matters for security, weather performance and lifetime costs. Cheap imitations may look similar at first glance; however, problems such as corrosion, premature wear and poor alignment are common. The following practical checks and fitting tips will help you identify inferior components and make the right choice.

Common weak points in cheap uPVC window parts

Understanding where manufacturers commonly cut corners helps when inspecting components before purchase. Typical weak points include:

- Material quality: low-grade zinc alloys and thin steel plate that bend or corrode quickly.

- Surface finish: poor plating or powder coat that chips or flakes, exposing base metal to rust.

- Internal components: absence of proper bushes, hardened pins or nylon guides leading to increased play.

- Spindles and screws: incorrect spindle lengths, undersized screws that strip or fall out.

- Locking mechanisms: simplified cams or stamped parts that wear faster than machined pieces.

- Seals and gaskets: low-density rubber that compresses permanently and causes draughts or leaks.

Visual and tactile checks: what to inspect before buying

Carry out these quick checks when ordering or receiving parts:

- Weight and feel: higher quality handles and espagnolette gear feel solid; light, tinny parts are suspicious.

- Finish: examine the paint or chrome under good light; look for uneven coating, runs, or flaking around edges and screw holes.

- Markings: reputable manufacturers laser-etch or stamp batch numbers, standards and brand names; blank components may be aftermarket junk.

- Fit and movement: operate the handle and latch; smooth, consistent action indicates proper bushes and lubrication.

- Screw threads and holes: check that thread form is clean and screws seat without cross-threading; poor threads strip easily.

- Spindle and square sizes: measure the spindle length and square size to ensure compatibility; cheap parts often use non-standard sizes.

Standards and documentation to request

Ask suppliers for evidence that parts meet recognised standards and for traceability documents. Key items:

- Corrosion resistance to BS EN 1670: indicates appropriate plating and performance in coastal or polluted environments.

- CE or UKCA marking where applicable: confirms compliance with relevant product directives.

- Manufacturer warranty: longer, clear warranties indicate confidence in product durability.

- Datasheets: materials, finish specifications and maintenance recommendations help you judge quality.

- Secure by Design or similar approvals where security is critical: especially for properties where insurance or certification matters.

Trade-focused technical checks

For glazing contractors and window fitters, deeper inspection avoids call-backs:

- Espagnolette bars: check profile strength and connection method to the locking gearbox; end connections should be crimped and secured, not merely pushed in.

- Shoots and keeps: plate thickness and screw hole reinforcement matter; thin keeps deform and screw holes elongate under use.

- Friction stays and hinges: look for stamped part numbers, proper rivets or bolts and adequate lubrication points; cheap stays bend or vibrate.

- Reinforcement in frames: ensure steel or aluminium reinforcements are present where specified; thin or absent reinforcement leads to sagging sashes.

- Multipoint locks: verify the operation of rollers, latch dogs and deadbolts; all should engage simultaneously and without heavy force.

DIY buyer and fitter tips

Homeowners can save money with careful buying and correct fitting. Follow these practical steps:

- Measure twice: record spindle length, backset, screw centres and handle offset; bring the old part as a template when possible.

- Order from reliable suppliers: choose trade suppliers with clear return policies and technical support; avoid very low-priced marketplaces without guarantees.

- Inspect before installation: confirm parts match your measurements and are defect-free before starting the job; return any suspect items.

- Use appropriate fasteners: stainless or zinc-coated screws of correct length prevent corrosion and avoid punching through the profile chamber.

- Grease moving parts: apply a light lithium or silicone grease to spindles, cams and friction stays during installation for smooth operation.

- Adjust keeps and strike plates: a misaligned keep can make a good lock feel faulty; small adjustments often solve sticking or rubbing.

- Replace seals when necessary: new gaskets and pile seals restore weatherproofing; cheap seals compress too much and should be avoided.

Signs that cheap parts are already causing problems

Recognise common failure symptoms so you can act before a small issue becomes a larger repair:

- Handles become loose quickly or play increases: indicating poor bushes or grub screws.

- Locking points fail to engage fully: cams or rollers may be undersized or worn.

- Visible rust or white powder around plated parts: sign of inadequate corrosion protection.

- Windows drop or stick in the frame: suggests weak reinforcement or bent hinges.

- Excessive draughts and condensation: poor seals or incorrect packing cause thermal and weather performance loss.

Where to source reliable uPVC window parts

Prefer established trade suppliers and brands that provide technical support, clear part numbering and aftercare. Ask for product codes and fitment instructions. If you are replacing an older item, confirm compatibility: modern locking gear and handles are not always direct drop-in replacements for legacy systems.

Recommended Products

Based on this article, you may find these products helpful:

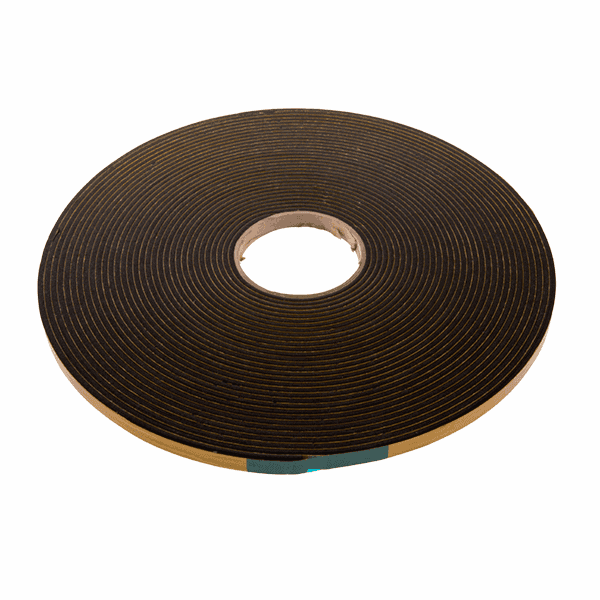

- Structural Glazing Tape - 20mm

- Security Glazing Tape

- Top Hung Friction Stay - 12"

- ERA Egress (Fire escape) Friction Stay

- TSS Standard Friction Stays – 13mm & 17mm Stack Height

Conclusion and next steps

Spotting cheap imitations of uPVC window parts saves time, money and protects security and energy performance. Prioritise material quality, correct dimensions, manufacturer documentation and a smooth operation when inspecting components. For trade professionals: insist on datasheets and standards compliance before purchasing in volume. For DIYers: measure carefully and order from reputable suppliers to avoid mismatches and premature failures.

Next steps: if you need help identifying a part or choosing a compatible replacement, consult the double glazing supplies hub at /guides/double-glazing-supplies or contact a trusted trade supplier for technical assistance and genuine, certified components.