Troubleshooting Espagnolette Problems: A Trade Fitter's Checklist

Troubleshooting Espagnolette Problems: a trade fitter's checklist for diagnosing and fixing common espagnolette faults on windows and French doors. Whether...

Troubleshooting Espagnolette Problems: a trade fitter's checklist for diagnosing and fixing common espagnolette faults on windows and French doors. Whether you are a homeowner trying a DIY repair or a trade professional preparing for a call-out, this post covers the practical checks, likely causes and reliable remedies for espagnolette faults.

How an espagnolette lock works: essentials for diagnosis

An espagnolette is a mechanical locking system commonly used on casement windows and French doors: a handle operates a gearbox or cam which drives vertical rods or shootbolts into keeps at the head and cill. On modern systems the handle turns a square spindle; the gearbox converts that rotation into linear movement of rods. Failure can occur at the handle, spindle, gearbox, rods, keeps or fixings. Knowing how the parts interact helps isolate the fault quickly.

Common problems and what they indicate

- Handle is loose or spins freely: likely a stripped gearbox, broken spindle, or worn follower.

- Handle won’t return to the locked position: obstructed rods, seized mechanism, or bent rod.

- Lock operates but rods do not move: gearbox failure or disconnected rods; check cranked cams and connector clips.

- Difficult to close door or window before locking: misaligned keeps, swollen timber, or faulty compressive gasket.

- Lock engages but door/window rattles: keeps worn or set too loose; keep position needs adjustment.

- Key won’t turn or locks intermittently: broken key barrel, seized euro cylinder or poor spindle engagement.

- Corrosion, paint or grit build-up: mechanism binding or seized screws, common on older timber or aluminium frames.

Trade fitter’s step-by-step troubleshooting checklist

Use this checklist on site to identify the root cause efficiently. Start with visual checks then move to mechanical tests.

- Visual inspection: look for missing screws, fractured plastic covers, paint near moving parts and corroded fixings.

- Operate the handle with the door/window open: observe whether the gearbox rotates and whether rods move. Note any slack or intermittent engagement.

- Remove the handle and escutcheon: inspect the spindle for wear or play; standard spindles are 7mm or 8mm square in domestic gearboxes; measure before ordering replacements.

- Check the gearbox: if the follower or cam is stripped the handle will spin without moving rods. Gearboxes often come as modular units for quick replacement.

- Inspect rods and connectors: look for bent rods, broken snap-in connectors or sliding cams that are seized in guide channels.

- Examine keeps and striker plates: check for wear or incorrect set; you may need to re-position keeps within their elongated screw slots to regain compression.

- Test locking under load: close the window and operate the lock; if it requires excessive force the issue is alignment rather than the gearbox.

Adjustment, repair and replacement tips

Some jobs are straightforward DIY; others are trade-level. Use these practical fixes depending on diagnosis.

- Tightening loose handles: remove handle grub screw, fit a new grub screw if rounded. Use a correct-size Allen key; avoid over-tightening which can strip threads.

- Replacing spindles: match length and square size; if the spindle is mushroomed or twisted replace it and check the handle bushes for wear.

- Gearbox replacement: if stripped, replace the whole gearbox unit; many systems have standard backsets and spindle positions but always confirm before ordering. Keep a small stock of common gearboxes for faster call-outs.

- Rod/connector repair: replace snap-in connectors or secure rods with new clips; if rods are bent replace them rather than attempting to straighten; bending weakens the steel.

- Keep realignment: loosen keep screws, move keep to engage the bolt with minimal force, then tighten. Use packers behind keeps if screw slots are inadequate for fine adjustment.

- Seized or corroded parts: apply a penetrating lubricant and free moving parts carefully; replace corroded screws and rivets. For painted-over locks carefully remove paint with a scraper and touch-up afterwards.

- Key/cylinder issues: if the cylinder is damaged replace it and re-code where applicable; ensure the cylinder tailpiece engages the gearbox correctly.

Lubrication and maintenance: what to do and what to avoid

Regular maintenance prevents many espagnolette issues. Clean and lubricate at least once per year for seaside properties or more frequently in heavy-use installations.

- Use silicone spray or a light machine oil on metal sliding parts and cams; these repel dirt and do not gum up.

- Avoid thick grease on locks inside sealed channels; it attracts dust and can clog the mechanism.

- Use graphite powder for keyways; avoid oiling the inside of euro cylinders which can attract grit.

- Check and replace worn plastic guides and bushes to prevent excessive gearbox wear.

DIY vs trade: when to call a professional

Homeowners can handle cleaning, lubrication, handle replacement and simple keep adjustments. Call a trade professional or specialist when:

- There is a structural alignment issue: warped frames, sagging doors or large adjustments needed at hinges.

- Gearbox or multipoint mechanism replacement is required and you are uncertain of compatibility; incorrect parts can compromise security.

- There are signs of forced entry or compromised security; a competent fitter should assess whether the door meets current standards and advise upgrades.

- Replacement requires cutting or welding bespoke rods; specialist equipment or manufacturer parts may be necessary.

Practical kit list for trade fitters

- Spare spindles (7mm and 8mm), universal gearboxes, and a small selection of rods/connectors.

- Set of keeps/striker plates for various profiles and packers for fine adjustment.

- Rivet gun, selection of rivets and stainless screws; penetrating oil and silicone spray.

- Common lock cylinders and key blanks if door involves cylinder replacement.

- Basic diagnostic tools: torch, mirror, feeler gauges and a digital camera for evidence and customer sign-off.

Useful reference

For detailed part identification and further reading see our espagnolette window locks guide: /guides/espagnolette-window-locks. That resource lists common manufacturers, part codes and fitting diagrams to help with ordering correct replacements.

Recommended Products

Based on this article, you may find these products helpful:

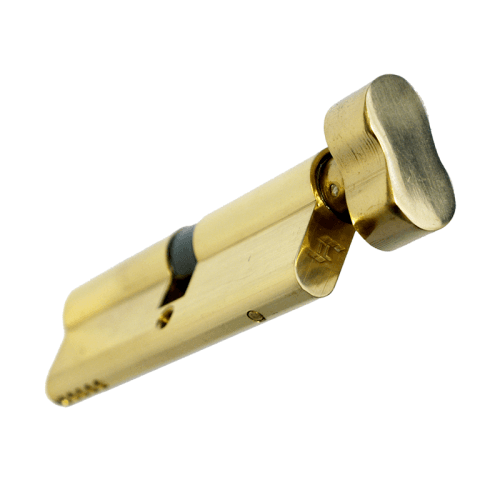

- TL Thumb Turn Euro Cylinder

- Ultion Plus TS007 3* Kitemarked Euro Key & Turn Cylinder

- ERAB Espagnolette Window Lock Universal Lock Replacement

- Avocet Slimline Offset Window Espag

- Multipoint Gearbox GU Old Style

Conclusion and next steps

Systematic inspection using the checklist above will identify most espagnolette faults quickly. Start with visual and mechanical checks, focus on the spindle, gearbox and keeps, and apply appropriate lubrication. Homeowners can tackle minor adjustments; for gearbox failures, structural alignment or security concerns call a trained fitter. If you need parts or a trade kit, contact Window Hardware Store for compatible gearboxes, spindles and keeps; provide measurements and photos for rapid parts matching.

Related articles

Window Gearbox Maintenance: Keeping Your Locks Working Smoothly

Window Gearbox Maintenance: Keeping Your Locks Working Smoothly A well maintained window gearbox keeps casement and tilt-and-turn windows operating smoothl...

Troubleshooting Shootbolt Problems: A Window Fitter's Guide

Troubleshooting Shootbolt Problems: A Window Fitter's Guide Shootbolts are a small but vital component in many modern window and patio door locking systems...

What Is a Shootbolt Lock? Complete Guide to Window Security

What Is a Shootbolt Lock? Complete Guide to Window Security What is a shootbolt? A shootbolt is a mechanical locking element commonly used in windows and d...