Door Handle Centres Explained: 92mm, 122mm, and 240mm

Choosing the right door handle is a small decision that makes a big difference on site. Tradespeople fitting doors every day and DIY enthusiasts tackling a weekend project both need to understand what...

Choosing the right door handle is a small decision that makes a big difference on site. Tradespeople fitting doors every day and DIY enthusiasts tackling a weekend project both need to understand what “centres” means and why 92mm, 122mm and 240mm centres matter. This guide explains centre measurements, typical applications, how to measure, and practical installation tips so you specify the correct door handle first time.

What does “centre” mean for a door handle?

In lock and handle terminology the centre is the distance between the spindle centre (the square shaft the handle turns) and the keyhole or cylinder centre. When you order a replacement or new set of handles you must match that centre to the lock case on the door. If the centres do not match the spindle will not engage the lock or the key will not line up with the cylinder, so the door handle will not function correctly.

Common centre sizes: 92mm, 122mm and 240mm – where they are used

These three centres cover the majority of residential and commercial work in the UK:

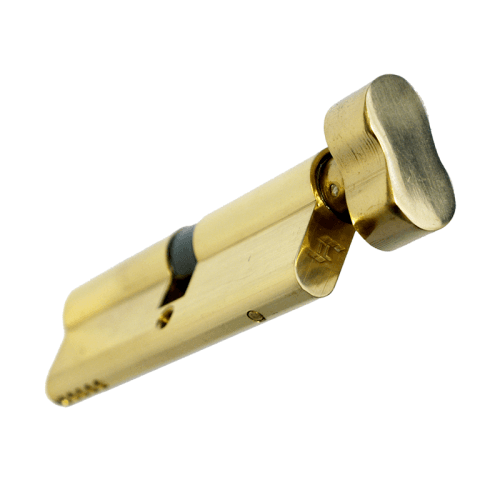

- 92mm centre: The most common size for modern uPVC, aluminium and composite doors with multipoint locks and euro cylinders. If you are fitting lever/lever or lever/lever furniture to a multipoint lock you will often need a 92mm door handle.

- 122mm centre: Frequently found on traditional timber doors and older mortice or sash locks where the lock case has a larger offset. Builders and joiners see 122mm on some rebated and older profile doors.

- 240mm centre: Common on pull handles, long-bar escutcheons and some external doors where the cylinder is mounted well below the follower; also used with rim locks and certain garage or utility doors. A 240mm door handle is often a backplate type with more separation between handle and key.

How to measure centres correctly

Measuring accurately avoids returns and wasted labour. Use the following steps when checking an existing door handle or specifying a new one:

- Open the door and remove the handle furniture if possible; expose the spindle and cylinder.

- Measure from the centre of the spindle to the centre of the keyhole or cylinder. Use a steel rule and take the measurement in millimetres; round to the nearest millimetre.

- If you cannot remove the handle, measure from the face of the handle backplate: measure the vertical distance from the centre line of the handle spindle to the centre of the key slot.

- Note other relevant dimensions: backset (distance from door edge to spindle centre), spindle length, handle projection and screw centres for fixing.

Always specify the exact centre measurement when ordering a door handle; adding the type of lock case and backset reduces the chance of mistakes.

Selecting the right door handle for the job

Beyond centres, consider these practical factors for trade installations:

- Lock type compatibility: confirm if the lock is a euro profile cylinder, oval cylinder, or mortice sash lock — that determines which handle/cylinder combination you need.

- Spindle size and length: traditional square spindles are usually 8mm; verify length to clear door thickness and any furniture or plates.

- Fixing centres and screw length: ensure screws engage the lock or the opposite side properly; for composite doors you may need longer screws or packers.

- Weather and security: external door handle sets should be specified with corrosion-resistant finishes and suitable for the euro cylinder type you plan to use.

- Aesthetic and ergonomic needs: choose handle style and backplate size to suit the door and building use; a 240mm door handle backplate can give a more architectural look and better weather protection.

Installation tips for tradespeople and competent DIYers

When fitting handles with 92mm, 122mm or 240mm centres, follow these practical tips:

- Pre-fit check: test fit the spindle into the lock case before tightening screws to ensure free movement and correct alignment with the cylinder.

- Use correct packers: for rebated doors or doors with thick seals you may need packers behind the backplate to prevent binding.

- Torque and movement: avoid over-tightening through-bolts or roses; compressing the plate can cause stiffness in the mechanism.

- Reversible handles: many modern door handle sets are reversible; check lever direction and hand the door appropriately before final fixing.

- Replace cylinder if necessary: if you fit a new 92mm door handle to a door with an outdated cylinder position consider replacing the cylinder with a suitable euro profile to match the handle centre.

Common faults and how to avoid them

Matching centres avoids many problems, but tradespeople should also watch for:

- Incorrect spindle length causing binding or loose handles; always carry common spindle lengths on site.

- Mismatched screw centres that leave the handle insecure; measure screw positions before ordering a set.

- Handle slop from worn follower or incorrect spindle size; replace the lock case or spindle rather than forcing a misfit handle.

- Water ingress around long backplates on external doors — use correct sealing and check plate fit to prevent corrosion around a 240mm door handle backplate.

Knowing how to measure and when to use 92mm, 122mm or 240mm centres will save time, avoid call-backs and keep installations secure. If in doubt, remove the existing furniture and measure the spindle to cylinder distance in millimetres; specify the centre, backset and spindle length when ordering your door handle to ensure a smooth fit.

Conclusion: Matching the centre measurement is one of the most important steps when specifying or replacing a door handle. The 92mm centre is the most common for modern multipoint doors, 122mm appears on many traditional timber fittings, and 240mm suits larger backplate and pull-handle arrangements. Accurate measurement, correct spindle selection and sensible installation practice ensure a professional result on every job.

Related Reading

Explore more guides on related topics:

- 3 Star Cylinder Explained: The Highest Level of Door Security

- Anti Arson Letterbox: How Fire-Resistant Letterboxes Protect Your Home

- Flag Hinges

Recommended Products

Based on this article, you may find these products helpful:

Part of our guide:

Complete Guide to Door Handles