Door Handle Backplate Sizes: Standard UK Dimensions

Choosing the right door handle backplate is a small but important part of a successful hardware specification or installation. For tradespeople, fabricators and DIY enthusiasts in the UK, understandin...

Choosing the right door handle backplate is a small but important part of a successful hardware specification or installation. For tradespeople, fabricators and DIY enthusiasts in the UK, understanding standard sizes, fixing centres and compatibility with locks can save time on site and reduce return trips. This guide explains typical door handle backplate sizes, how to measure for replacements, and practical installation considerations so you get the correct component first time.

What is a door handle backplate and why size matters

A door handle backplate is the rectangular or decorative plate that sits between the handle and the door face. Backplates provide a mounting surface for the spindle and fixings, conceal existing holes, and influence the aesthetic of a door. Size matters because the backplate must align with the lock or latch, cover previous holes, and allow the handle to operate freely. Incorrect sizing can lead to misaligned spindles, exposed screw holes, or handles that stick on rebated edges.

Standard door handle backplate dimensions in the UK

There are several common backplate sizes used across residential and commercial doors. While manufacturers may offer a wider range, the following are typical standards you will encounter:

- 160 mm x 42 mm: Compact backplate for minimal, contemporary hardware; commonly used for internal latch doors.

- 175 mm x 50 mm: Mid-size backplate popular for internal doors in domestic settings; good balance between coverage and discreet appearance.

- 240 mm x 40–55 mm: Long backplate often used where additional screw fixing is needed or to cover previous furniture holes; used on entrance doors where visual proportion is required.

- 290 mm x 55 mm (or larger): Oversize backplates for period or decorative furniture; used to recreate historical proportions or to hide multiple previous fixings.

Thickness also varies: common thicknesses are 2 mm to 3 mm for modern plated steel or aluminium, and up to 6 mm for heavy brass or pewter plates. Keep in mind that thickness affects the clearance between handle and door face, and may influence whether certain rose-mounted handles can be fitted.

Key measurements to check before ordering

Before purchasing a replacement door handle backplate, confirm these measurements on site:

- Overall height and width of the existing plate or the area to be covered.

- Centres: the distance between centre of the spindle hole and keyhole or euro cylinder hole. Common centres include 57 mm (handle to thumb-turn) and 92 mm (handle to euro cylinder); confirm specific lock type.

- Spindle square size: typical sizes are 7 mm or 8 mm for many lever sets; some commercial hardware uses 9 mm.

- Screw positions and fixing centres: measure vertical offset from top or bottom edge to existing screw holes if you need to re-use holes.

- Backset: distance from the edge of the door to the centre of the spindle/lock—ensure handle operation clears latch or lock case.

Document these in millimetres and, when in doubt, take a photo with a tape measure for the supplier to confirm compatibility.

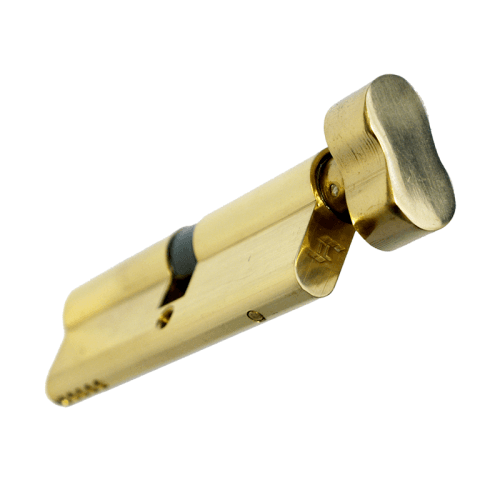

Compatibility with locks and cylinders

Door handle backplate compatibility depends primarily on the lock type in the door:

- Latch-only doors: small to mid-size backplates work well; ensure spindle aligns with latch centre.

- Euro cylinder locks: you will need a backplate with a correctly positioned cylinder hole and the right centre measurement to maintain security and operation.

- Mortice locks: check the distance between the handle spindle and the keyhole on the plate to match the lock centre; some mortice locks use 57 mm centres, others vary.

- Toilet or bathroom privacy locks: backplates can include thumb turn cut-outs or separate fittings; verify thickness so the thumb turn operates smoothly.

For security doors, choose a backplate that does not hinder anti-snap or anti-drill cylinder features; avoid altering cylinder protection by fitting an inappropriate plate.

Practical installation tips for tradespeople

Follow these practical steps to ensure a neat installation:

- Measure twice: verify overall plate size, spindle size and centres before ordering replacements.

- Use masking tape to mark screw positions on the door face and pilot drill to avoid splitting timber; countersink screws if the backplate is flush.

- If covering previous holes, choose a plate that overlaps by at least 10–15 mm in each direction to ensure full concealment.

- Check door rebate clearance: longer backplates can foul rebated door edges or other hardware; dry-fit first.

- Match finish and wear resistance to the environment: brass or stainless steel for external doors; plated finishes for internal applications where aesthetics matter.

- When replacing on a fire door, ensure the new backplate and fixings do not compromise fire-rating compliance; consult the door certificate where required.

Choosing the right backplate for appearance and durability

Beyond pure dimensions, consider style and durability for long-term satisfaction. Slim rectangular backplates suit contemporary schemes; ornate wide plates fit period properties. For high-traffic doors choose harder wearing finishes and thicker plates to resist deformation. If specifying for an entire project, standardise on one backplate height and centres where possible to simplify ordering and spare parts management.

Finally, always check the supplier’s technical sheets for exact hole centres and spindle sizes. If you are unsure, send clear site photographs with measurements to your supplier for clarification before cutting rebate or mortice work.

Conclusion

Understanding standard door handle backplate sizes will make specifying, ordering and installing door furniture quicker and more reliable. Measure overall plate dimensions, spindle and keyhole centres, and confirm screw positions before buying. Select the correct thickness and finish for the application and check lock compatibility to avoid on-site rework. With the right measurements and a few simple checks, tradespeople and DIYers can fit a backplate that looks right and functions reliably for years.

Related Reading

Explore more guides on related topics:

- How to Replace a uPVC Door Lock: Step-by-Step DIY Guide

- 3 Star Cylinder Explained: The Highest Level of Door Security

- Anti Arson Letterbox: How Fire-Resistant Letterboxes Protect Your Home

Recommended Products

Based on this article, you may find these products helpful:

Part of our guide:

Complete Guide to Door Handles