3 Star Cylinder Sizes: Finding the Right Fit

3 Star Cylinder Sizes: Finding the Right Fit Choosing the correct 3 star cylinder is critical for security and smooth operation of doors and some windows. ...

3 Star Cylinder Sizes: Finding the Right Fit

Choosing the correct 3 star cylinder is critical for security and smooth operation of doors and some windows. Whether you are a homeowner replacing a worn lock or a trade professional selecting stock for installs, understanding cylinder sizing, types and installation practicalities will save time and prevent callbacks.

What does a 3 star cylinder mean?

A 3 star cylinder refers to a euro cylinder that has achieved the highest rating under the TS007 classification scheme. These cylinders are designed to resist common forced-entry methods including snapping, drilling, bumping and picking. For homeowners a 3 star cylinder offers enhanced protection and often helps meet insurance requirements for external doors. For installers, it is a product spec that communicates robust anti-attack features to customers.

Understanding euro cylinder measurements

Euro cylinders are sized by the distance from the centre of the fixing screw to each end. Measurements are usually stated as X/Y in millimetres: for example 35/45 means 35mm from the screw to one end and 45mm to the other, giving an overall length of 80mm. Cylinders can be symmetrical or asymmetric; the latter are common where handle sets, escutcheons or internal furniture require different clearances on each side.

- Centre fixing point: the locating screw on the edge of the door is the reference point for measurement.

- Overall length: the sum of both sides (X + Y) gives the total cylinder length.

- Projection: keep cylinder projection beyond the face of the door minimal; excess projection increases vulnerability to attack and can affect handle operation.

Common sizes and how to choose

Below are common profiles you will encounter in domestic and light-commercial installations. Always measure the existing cylinder before ordering a replacement.

- 30/30 = 60mm: compact doors and some internal applications.

- 30/35 = 65mm; 30/40 = 70mm: slightly asymmetrical applications.

- 35/35 = 70mm; 35/40 = 75mm; 35/45 = 80mm: very common for uPVC and composite doors.

- 40/40 = 80mm; 45/45 = 90mm: common on thicker doors or where larger handle furniture sits either side.

- 50/50 = 100mm and larger: used on particularly thick doors or special commercial doors.

For tradespeople: stock the most commonly requested asymmetric sizes such as 35/45, 35/35 and 40/40. For homeowners: measure both sides from the fixing screw to the external face to determine the correct X/Y specification.

Compatibility with locks, multipoint systems and handles

Euro cylinders are widely used in multipoint door locks, uPVC doors and some commercial applications. When fitting into a multipoint lock ensure that:

- The cylinder length matches the door furniture and lock case centre; incorrect length can prevent the lock from engaging cleanly.

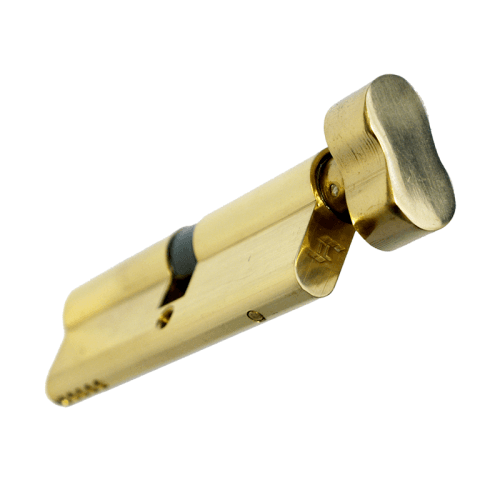

- Thumbturn cylinders are used where internal user convenience is needed; double cylinders (key either side) are suitable where no internal thumbturn is wanted but allow locking from both sides.

- For doors with heavy handles or escutcheons you may need an asymmetric cylinder to avoid interference and ensure comfortable operation.

Practical replacement and installation advice

Tools required: cross-head screwdriver, tape measure, replacement cylinder, and a clean cloth. Basic steps for removing and replacing a euro cylinder are:

- Open the door and locate the centre fixing screw on the edge of the door. This secures the cylinder to the lock case.

- Partially insert the key and rotate it slightly until the cam aligns; this allows the cylinder to slide free once the fixing screw is removed.

- Remove the fixing screw, then gently pull the cylinder out using the key while rotating as needed to free the cam. Note: some cylinders can be tight if corroded; do not force with pliers as this can damage the keyway.

- Measure from the centre of the fixing hole to each end; record the exact millimetres before ordering replacement.

- Fit the new 3 star cylinder, insert the fixing screw loosely, check that the key turns smoothly and that the lock operates through the full cycle, then fully tighten the screw without over-stressing the case.

Trade tip: always confirm the orientation before tightening. If a cylinder is asymmetric it will only fit one way around; incorrect orientation can cause the cam to bind and lead to malfunction.

Security best practice and accessories

Even with a 3 star cylinder you should consider complementary measures to maximise security:

- Use reinforced cylinder protection or anti-snap escutcheons; these reduce the chance of grab-and-snap attacks.

- Consider securing handles with bolts that resist removal; insecure handle fixings can render a high-spec cylinder less effective.

- For rental or multi-occupant properties consider master-keying or keyed-alike options from reputable suppliers; ensure this is planned at order stage as it affects keying and stock control.

- Lubricate periodically with a graphite or dry lubricant; avoid oil-based products that attract dirt.

Maintenance and troubleshooting

Common issues are sticking keys, difficulty turning, or cylinders that protrude. Simple checks often resolve problems:

- If the key is stiff: check alignment of the handle and lock case; tighten any loose furniture; clean and apply graphite lubricant.

- If the cylinder is loose or projecting: ensure the correct length was fitted; replace with a properly sized cylinder and use a protective escutcheon.

- If the cylinder will not remove: double-check key rotation to align the cam; try one extra degree of rotation rather than forcing.

Recommended Products

Based on this article, you may find these products helpful:

- TL Thumb Turn Euro Cylinder

- Ultion Plus TS007 3* Kitemarked Euro Key & Turn Cylinder

- Multipoint Gearbox GU Old Style

Conclusion and next steps

Picking the correct 3 star cylinder comes down to accurate measurement, understanding the door and handle configuration, and choosing the right type for the application: thumbturn, double or single. Tradespeople should keep a small range of common asymmetric sizes in stock to reduce site delays. Homeowners can measure the existing cylinder from the centre fixing screw to both faces and order the correct X/Y size.

Next steps: measure the existing cylinder now, note whether you need a thumbturn or double cylinder, and consult your supplier for compatible 3 star cylinder models and escutcheon options. If you are unsure, contact a locksmith or a trusted trade supplier with photos and measurements; a short call often avoids an incorrect order.

Products mentioned in this article

Related articles

What Is a Thumb Turn Cylinder? Convenience vs Security

What Is a Thumb Turn Cylinder? Convenience vs Security What is a thumb turn cylinder? A thumb turn cylinder is a type of euro-profile lock cylinder that ha...

Thumb Turn Cylinder vs Panic Bar: Exit Options Compared

Thumb Turn Cylinder vs Panic Bar: Exit Options Compared examines two very different approaches to door egress and security. The thumb turn cylinder is a co...

Thumb Turn Cylinder Sizes: Finding the Right Length

Thumb Turn Cylinder Sizes: Finding the Right Length Choosing the correct thumb turn cylinder is vital for security, smooth operation and a neat finish on d...