Euro Cylinder Not Turning? Troubleshooting Common Problems

Euro Cylinder Not Turning? Troubleshooting Common Problems When a euro cylinder lock refuses to turn it causes frustration for homeowners and trade profess...

Euro Cylinder Not Turning? Troubleshooting Common Problems

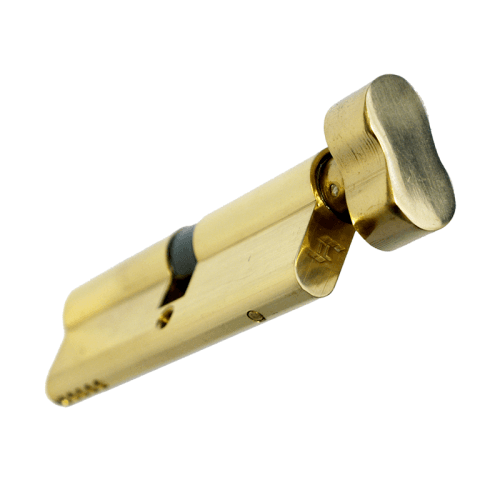

When a euro cylinder lock refuses to turn it causes frustration for homeowners and trade professionals alike. Euro cylinders are widely used in uPVC, composite and timber doors; they operate a cam or follower that drives the multipoint gearbox or deadbolt. A non-turning cylinder can be due to a simple alignment issue or a mechanical failure that needs a specialist replacement. Below are practical steps to diagnose and resolve the most common problems safely and efficiently.

Common symptoms and their likely causes

- Key won’t insert fully or is hard to insert: debris, worn key profile or incorrect key blank.

- Key turns partly then stops: misalignment of the door or lock mechanism binding due to a seized multipoint gearbox.

- Key turns in the cylinder but the handle/multipoint does not operate: broken or stripped cam; follower not engaging.

- Key snaps or gets stuck: metal fatigue, damaged profile or forced entry attempts; anti-snap features may have partially failed.

- Cylinder rotates freely without moving locks: cylinder not actually connected to the spindle or centre follower; retaining screw loose or missing.

Initial DIY checks: quick and safe tests

Before removing the cylinder, carry out some non-invasive tests that will often identify the problem quickly:

- Check door alignment: close the door slowly and observe whether the lock engages smoothly into keeps; look for dragging at the top or bottom hinge which indicates sash sag.

- Try the spare key: this rules out a worn or damaged key. If the spare works, replace or file the worn key and consider a duplicate cut from the original pattern.

- Operate handle and lock while watching: does the spindle move when the key is turned? If not, the cam or follower may be broken.

- Inspect cylinder face: signs of snapping or shearing mean you need to replace the cylinder with a higher security anti-snap product, such as a TS007 3-star rated cylinder.

Lubrication and cleaning: what to use and what to avoid

A common cause of stiffness is dirt or old lubricant inside the keyway. Use a dry lubricant such as graphite powder or a PTFE spray designed for locks; these attract less dust. Avoid heavy oils or penetrating lubricants long-term; they can gum up multipoint systems and attract grit. Apply a small amount of graphite into the keyway, insert the key and work it gently to distribute the lubricant. If a spray is used, use it sparingly and wipe excess from the faceplate.

Removing and testing the cylinder

For both DIYers and trades, removing the cylinder is a useful diagnostic step. You will need a screwdriver and the correct key. Follow these steps:

- Open the door and locate the fixing screw on the edge of the door: this secures the cylinder in place.

- Partially insert the key and turn it slightly so the cam aligns with the body of the cylinder; this lets the cylinder slide free when the screw is removed.

- Remove the fixing screw and gently withdraw the cylinder; you may need to jiggle the key while pulling out to align the cam.

- With the cylinder out, insert the key and test rotation off the door. Smooth rotation indicates the issue is in the multipoint gearbox, spindle or door alignment; stiffness or no rotation means the cylinder is faulty.

Diagnosing specific faults

- Cam or follower failure: if the cylinder turns when out of the door but does not operate the lock when fitted, the cam or internal follower may be sheared or the connection to the spindle is stripped. Replace the cylinder; consider upgrading to a hardened anti-snap model.

- Multipoint gearbox binding: if the cylinder turns freely out of the door but the lock is stiff when installed, the gearbox may be seized or internal sliders are misaligned. Inspect keeps, clean and lubricate the multipoint mechanism; trades should check gearbox wear and replace the lock case if necessary.

- Door misalignment: an out-of-square door causes locking points to bind. Adjust hinges, use hinge packers or tweak striker plates to realign keeps. Minor adjustments can restore smooth operation without replacing the cylinder.

- Anti-snap attack: if the front of the cylinder shows a fractured section, replace immediately with a TS007 3-star cylinder; document for insurance purposes if forced entry occurred.

- Wrong cylinder length: an incorrectly sized cylinder may be under strain against the escutcheon or handle; measure the existing cylinder across the face to each end and specify equal or asymmetric lengths when ordering replacements.

Trade tips for efficient repairs and replacements

- Carry a selection of common lengths: 35/35, 35/45, 40/50 and asymmetric sizes to avoid repeat calls; many installers keep a stock of anti-snap TS007 3-star cylinders.

- When replacing cylinders on multipoint doors, fit a cylinder with the correct finish and cam profile; the profile must match the lock case to engage properly.

- Check for keyed-alike requirements and advise customers on masterkeying options; explain the trade-off between convenience and security.

- When removing a broken key, use a broken key extractor or pin hook; if the key is flush with the cylinder, extractor kits are often the fastest solution. Avoid drilling unless as a last resort and only if you can replace the cylinder immediately.

- For properties with insurance requirements, specify cylinders that meet British Standards and Secured by Design where required.

When to call a locksmith or a specialist

If the cylinder is jammed due to snapped components, or if the multipoint gearbox is seized and requires replacement, call a qualified locksmith or door hardware specialist. Forced entry incidents require professional attendance to restore security and to provide the correct documentation for insurance. Trades may escalate to a specialist if bespoke hardware or high-security masterkey systems are involved.

Recommended Products

Based on this article, you may find these products helpful:

- TL Thumb Turn Euro Cylinder

- Ultion Plus TS007 3* Kitemarked Euro Key & Turn Cylinder

- Multipoint Gearbox GU Old Style

- In-Line Window Mechanism

- Offset Window Mechanism

Conclusion and next steps

Start with simple checks: try a spare key, lubricate with graphite or PTFE, and verify door alignment. If removing the cylinder shows smooth rotation, the fault is likely in the multipoint mechanism or door geometry; if the cylinder is stiff or won’t rotate off the door, replace it. For signs of forced entry or snapped cylinders, fit a TS007 3-star anti-snap replacement and seek locksmith assistance if needed. For more detailed technical information on euro cylinder options and measurements, visit our pillar resource at /guides/euro-cylinders. If you are unsure about any step, contact a professional installer to avoid compromising security.

Related articles

What Is a Thumb Turn Cylinder? Convenience vs Security

What Is a Thumb Turn Cylinder? Convenience vs Security What is a thumb turn cylinder? A thumb turn cylinder is a type of euro-profile lock cylinder that ha...

Thumb Turn Cylinder vs Panic Bar: Exit Options Compared

Thumb Turn Cylinder vs Panic Bar: Exit Options Compared examines two very different approaches to door egress and security. The thumb turn cylinder is a co...

Thumb Turn Cylinder Sizes: Finding the Right Length

Thumb Turn Cylinder Sizes: Finding the Right Length Choosing the correct thumb turn cylinder is vital for security, smooth operation and a neat finish on d...