How Anti-Snap Cylinders Work: Breakaway Section Explained

How Anti-Snap Cylinders Work: Breakaway Section Explained Anti snap cylinder locks have become the standard response to a widespread method of forced entry...

How Anti-Snap Cylinders Work: Breakaway Section Explained

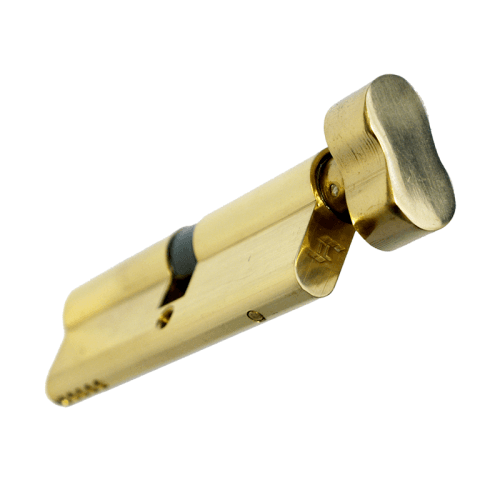

Anti snap cylinder locks have become the standard response to a widespread method of forced entry: cylinder snapping. This post explains how an anti snap cylinder protects a door, how the breakaway or sacrificial section works, and what tradespeople and competent DIYers need to know when specifying or fitting one. For further technical details on euro cylinders generally, see our pillar resource: /guides/euro-cylinders.

What is cylinder snapping and why it matters

Cylinder snapping is a physical attack where an intruder uses pliers, a screwdriver or a purpose-made tool to break a euro-profile cylinder at a weak point. Once the outer portion is removed the cam and inner mechanism can be manipulated and the lock opened. Many older or budget euro cylinders protrude beyond protective hardware; that protrusion provides a simple lever point for attackers.

Because the attack is quick and noisy but effective, manufacturers developed anti snap cylinder designs to limit the damage and keep the lock secure even if the outer section is forced.

How the breakaway section works

An anti snap cylinder uses a deliberately engineered weak section: the breakaway or sacrificial element. This is usually positioned at the external end of the cylinder so that, under a snapping attempt, the outer sleeve shears off at a controlled point. Crucially, the inner core, cam and locking mechanism remain intact within the door; the sacrificial piece absorbs the force and detaches, preventing direct access to the cam.

Key design features you will find on modern anti snap cylinders include:

- Pre-scored or engineered groove that defines the break point;

- Reinforced central section around the cam to resist further attacks;

- Hardened steel inserts or anti-drill pins to resist drilling attempts;

- Anti-bump or anti-pick features in the pin stack to resist covert attacks;

- Reduced cylinder projection beyond the escutcheon to avoid levering points.

Standards and certification to look for

For both homeowners and installers, certifications are a quick indicator of performance. In the UK the TS007 2014 standard grades cylinders using a star system; a TS007 3-star cylinder provides a higher level of resistance to snapping and is commonly recommended for external doors. Look for cylinders with a Kitemark or Sold Secure rating where appropriate, and consider products listed by Secured by Design for the highest recognised specification.

Practical trade advice when specifying anti snap cylinder

For installers specifying a cylinder for an external composite or uPVC door, follow these rules of thumb:

- Choose a TS007 3-star or equivalent product for front and back doors;

- Measure the cylinder length accurately: the distance from the fixing screw to each end determines the correct size (example: 35/35, 30/40 etc);

- Ensure minimal cylinder projection beyond the faceplate and escutcheon: too much projection increases snap risk even with an anti snap cylinder;

- Fit a reinforced or anti-snap escutcheon and consider a cylinder protector plate for additional resistance;

- Where possible specify cylinders with anti-drill plates and hardened pins if a higher level of physical attack resistance is required;

- For multi-point locking doors check the cam position and the handle operation; some multipoint systems require specific cam types or neutral positions during removal and refit.

DIY replacement: safe step-by-step approach

If you are a competent DIYer replacing a cylinder, these practical steps will help ensure a correct fit and safe operation. If you are unsure at any stage call a professional installer.

- Measure the existing cylinder: remove the handle or escutcheon if needed and note the distances from the central fixing screw to the outside and inside ends. Replace with the same overall length and proportions to avoid excess projection.

- Choose the correct product: select a recognised anti snap cylinder (TS007 3-star if you want the highest rating) with appropriate additional features such as anti-drill pins;

- Position the door: set the door so the cam is in the neutral position; this makes removal and insertion easier and avoids damage to the multipoint lock;

- Remove the fixing screw and withdraw the old cylinder carefully; if it resists check that the handle or follower is in the correct position;

- Insert the new anti snap cylinder ensuring the cam aligns with the mechanism; secure with the correct fixing screw and tighten to manufacturer torque—do not overtighten as this can distort the cylinder;

- Test operation: with the door open turn the key to check the cam moves freely through the lock. Test from both sides; check that escutcheons and trim do not bind or allow the cylinder to protrude;

- Refit handles and trim; final test with the door closed to ensure the multipoint lock operates correctly and the key turns smoothly.

Common pitfalls and solutions

Several mistakes can undermine even the best anti snap cylinder. These include fitting the wrong length cylinder so it protrudes, using soft escutcheons that fail to protect the exposed end, and failing to check multipoint lock compatibility. To avoid these problems:

- Always measure twice and order the correct length;

- Fit reinforced escutcheons or a cylinder protector plate, especially on uPVC and composite doors;

- Confirm the new cylinder’s cam type and position will work with the existing lock case;

- For exposed or highly vulnerable doors consider overlapping protection: a 3-star cylinder plus a protective escutcheon plus internal security furniture.

When to call a professional

Call a qualified locksmith or installer if you encounter seized lock parts, if the door is part of a complex multipoint system and you are unsure how to neutralise the cam, or when work requires drilling or strengthening of the door core. Professional fitters will also be able to supply and fit Secured by Design approved systems and provide warranty documentation that many insurers value.

Recommended Products

Based on this article, you may find these products helpful:

- TL Thumb Turn Euro Cylinder

- Ultion Plus TS007 3* Kitemarked Euro Key & Turn Cylinder

- Multipoint Gearbox GU Old Style

- In-Line Window Mechanism

- Offset Window Mechanism

Conclusion and next steps

Anti snap cylinder technology uses a sacrificial breakaway section to stop an attacker reaching the cam and opening the lock; combined with reinforced central sections, anti-drill and anti-pick features, these cylinders significantly reduce the risk of forced entry. For best results specify TS007 3-star or equivalent cylinders, match the length exactly, and fit protective escutcheons. If you are unsure about compatibility with a multipoint lock or require a security upgrade, contact a trained installer or locksmith.

Next steps: measure your existing cylinder, review our euro cylinder guide at /guides/euro-cylinders, and consider upgrading to a recognised anti snap cylinder and protector plate for doors with external exposure.

Related articles

What Is a Thumb Turn Cylinder? Convenience vs Security

What Is a Thumb Turn Cylinder? Convenience vs Security What is a thumb turn cylinder? A thumb turn cylinder is a type of euro-profile lock cylinder that ha...

Thumb Turn Cylinder vs Panic Bar: Exit Options Compared

Thumb Turn Cylinder vs Panic Bar: Exit Options Compared examines two very different approaches to door egress and security. The thumb turn cylinder is a co...

Thumb Turn Cylinder Sizes: Finding the Right Length

Thumb Turn Cylinder Sizes: Finding the Right Length Choosing the correct thumb turn cylinder is vital for security, smooth operation and a neat finish on d...