How Euro Cylinders Work: Inside the Mechanism

How Euro Cylinders Work: Inside the Mechanism Understanding how a euro cylinder lock works helps both homeowners and trade professionals choose the correct...

How Euro Cylinders Work: Inside the Mechanism

Understanding how a euro cylinder lock works helps both homeowners and trade professionals choose the correct product, carry out safe replacements and diagnose common faults. This article explains the parts and operation of a euro cylinder lock, highlights common security features and gives practical trade and DIY advice for installation and maintenance.

What is a euro cylinder lock?

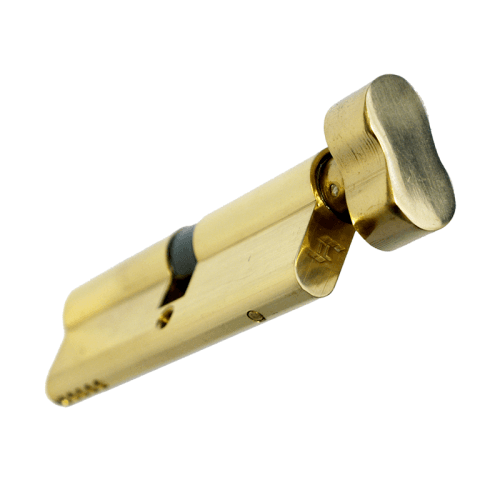

A euro cylinder lock is a widely used lock mechanism, particularly on uPVC, composite and aluminium doors across the UK. The cylinder fits into the door lock case and contains the locking components that react to the key. Euro cylinders come in different configurations: single, double, and half cylinders, plus cylinders with an integrated thumbturn. Many multi-point locking systems also use a euro profile cylinder to operate the central cam which engages the multi-point mechanism.

Core components and how they interact

The main components of a euro cylinder lock are straightforward; knowing them helps with diagnostics and selection:

- Shell: the outer casing that sits in the lock case and is held in place by a single retaining screw through the faceplate.

- Plug: the rotating part that accepts the key; when the correct key is inserted the plug rotates freely.

- Pin stacks: typically top and bottom pin stacks consisting of driver pins and key pins; they align at the shear line when the correct key is used.

- Shear line: the interface between plug and shell where correct pin alignment allows rotation.

- Cam: the central rotating element at the rear of the plug; it transfers rotation to the lock mechanism such as the latch or multi-point gearbox.

- Keyway: the slot where the key is inserted; profiles vary by manufacturer to control key duplication.

How the mechanism operates

Operation is simple in principle: the bitted key lifts each key pin to a height that aligns driver pins with the plug shell at the shear line; once all pins are aligned the plug rotates and the cam turns. The cam either retracts a latch or operates a multi-point locking gearbox; on double cylinders the cam will turn whether a key is used on either side, unless a thumbturn is fitted on one face.

Different cylinder types behave differently in use:

- Single cylinder: one keyed side, the other side is fixed or has a thumbturn; common on internal doors.

- Double cylinder: keyed on both sides; used where a keyed exit is required but note the safety implications in an emergency.

- Half cylinder: keyed on one side only; used where the cylinder only needs to operate a latch from one side.

Security features to look for

Modern euro cylinder locks include several anti-intrusion features; trade professionals and conscientious homeowners should specify these for external doors:

- Anti-snap: cylinders are designed with a sacrificial section so that, if attacked, the snapped section breaks away while leaving the inner mechanism intact; look for TS007 3-star accredited products for best protection.

- Anti-drill: hardened pins or inserts resist drilling attacks.

- Anti-pick and anti-bump: complex pin arrangements and specially profiled keyways reduce the chance of picking or bumping.

- Restricted key, or key control: reduces unauthorised key copying; useful for communal buildings or managed properties.

Practical trade advice: specifying and fitting

When specifying a euro cylinder lock, consider the following trade-focused points:

- Security rating: for external doors specify a cylinder with at least TS007 3-star or equivalent insurance-approved rating.

- Length: measure from the centre of the fixing screw to each end of the cylinder to choose the correct length; a cylinder that protrudes excessively is vulnerable to attack.

- Cam profile and gearbox compatibility: confirm the cam position and rotation match the lock case or multi-point gearbox.

- Finish and corrosion resistance: for aluminium or coastal properties choose corrosion-resistant finishes.

Fitting tips for installers: always test the new cylinder before fully securing it; ensure the bolt or deadlatch is retracted when removing the old cylinder, use the key to align the cam when pulling the cylinder out and do not overtighten the retaining screw which can bind the plug.

DIY removal and replacement: step-by-step

Homeowners with basic DIY skills can replace a cylinder safely. Typical steps are:

- Open the door and locate the retaining screw in the centre of the faceplate; remove or slacken it.

- Insert the key into the cylinder and turn it slightly to align the cam; this often allows the cylinder to slide out smoothly.

- Pull the cylinder out while holding the key in the turned position; if it does not pull free, check the bolt is fully retracted or try a small additional rotation.

- Measure the cylinder length before ordering a replacement; fit the new cylinder with the cam in the same orientation and slide it into place.

- Secure with the retaining screw, test operation with the door both open and closed and ensure the cylinder does not protrude beyond the faceplate excessively.

Maintenance advice: use a dry lubricant such as graphite or a silicone spray rated for locks; avoid oil-based lubricants which attract dirt. If a cylinder is stiff or sticky, lubricate first before assuming replacement is necessary.

Common problems and quick diagnostics

Typical faults and what they indicate:

- Stiff or hard to turn: often dirt or corrosion in the pin stacks; try lubricating and cycling the key several times.

- Key won’t turn: check the deadbolt is retracted and the cam is aligned; inspect for broken key fragments.

- Cylinder protruding after attack: replace immediately with an anti-snap TS007 3-star cylinder and report to insurer if required.

- Key sticks or jumps: worn key or internal wear; try a spare key and consider replacement if faults persist.

Recommended Products

Based on this article, you may find these products helpful:

- TL Thumb Turn Euro Cylinder

- Ultion Plus TS007 3* Kitemarked Euro Key & Turn Cylinder

- Multipoint Gearbox GU Old Style

- In-Line Window Mechanism

- Offset Window Mechanism

Conclusion: next steps

Understanding the inner workings of a euro cylinder lock helps with selecting the correct product and carrying out safe installation and maintenance. For external doors choose a high-security, anti-snap cylinder with the appropriate length and cam profile. For more detailed product comparisons and fitting diagrams visit our pillar page: /guides/euro-cylinders. If you are unsure about security requirements or encounter forced entry damage contact a qualified locksmith or your supplier for trade-level advice and replacement options.

Related articles

What Is a Thumb Turn Cylinder? Convenience vs Security

What Is a Thumb Turn Cylinder? Convenience vs Security What is a thumb turn cylinder? A thumb turn cylinder is a type of euro-profile lock cylinder that ha...

Thumb Turn Cylinder vs Panic Bar: Exit Options Compared

Thumb Turn Cylinder vs Panic Bar: Exit Options Compared examines two very different approaches to door egress and security. The thumb turn cylinder is a co...

Thumb Turn Cylinder Sizes: Finding the Right Length

Thumb Turn Cylinder Sizes: Finding the Right Length Choosing the correct thumb turn cylinder is vital for security, smooth operation and a neat finish on d...