Offset Window Handle Security Features: What to Look For

Introduction: Offset window handles are a common choice for modern casement windows and tilt-and-turn units; their design moves the handle off the centreline to clear trickier hardware or meet aesthet...

Introduction: Offset window handles are a common choice for modern casement windows and tilt-and-turn units; their design moves the handle off the centreline to clear trickier hardware or meet aesthetic requirements. For tradespeople and confident DIYers, understanding the security features to look for when specifying or fitting an offset window handle is vital. This guide explains the key security considerations, testing standards, and practical installation tips to help you choose handles that keep properties safe and compliant.

What is an offset window handle and why security matters

An offset window handle sits away from the centre of the handle spindle; the amount of offset varies to accommodate friction stays, restrictors, or the profile design. When you specify an offset window handle, you must consider how the offset affects engagement with the locking keeps, the leverage applied by intruders, and the compatibility with multipoint systems. A secure offset window handle is not just about the handle itself; it is about the whole locking system working together.

Key security features to look for

When assessing an offset window handle, check for the following security features:

- Key-locking option: A key-lockable offset window handle provides positive secondary locking when the window is closed; excellent for ground-floor openings and vulnerable areas.

- Positive locking spindle: A square spindle with anti-rotation design reduces the risk of the handle being forced off or sheared; ensure the spindle length and profile match the lock case.

- High-security fixings: Long, hardened steel screws and countersunk fixing plates resist extraction and tampering; look for handles supplied with appropriate screws for the frame material.

- Reinforced backplate: A reinforced or thicker backplate gives greater resistance to lever attacks and distributes load into the frame.

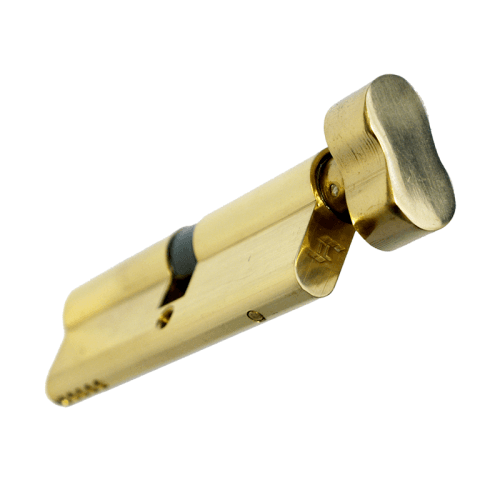

- Anti-snap and anti-drill features: If the handle incorporates a cylinder, select models with anti-snap, anti-drill and anti-bump protection; these are critical where euro cylinders are used.

- Certifications: Look for handles tested to recognised standards such as PAS 24 compliance or Secured by Design endorsement where applicable; also check corrosion resistance to BS EN 1670 for longevity.

Compatibility with lock cases and multipoint locks

Offset window handle selection must take the locking mechanism into account. A mismatch can compromise security and operation:

- Spindle size and length: Measure the required spindle length accurately; an incorrect spindle can prevent full engagement with the locking mechanism or allow play that weakens security.

- Offset measurement: Confirm the offset dimension to ensure handle clears stays or restrictors without placing undue leverage on the locking points.

- Multipoint engagement: For multipoint locks, ensure the handle provides the correct throw and torque to operate the cams or rollers reliably; some offset window handle designs include boosted leverage for heavy multipoint systems.

- Non-handed vs handed handles: Choose the correct handed version or a reversible handle to ensure the profile fits flush and offers the best resistance to forced entry.

Installation best practice for maximum security

Correct installation is as important as selecting a secure product. Follow these practical steps when fitting an offset window handle:

- Check template: Use the manufacturer's drilling template to position fixings correctly; misaligned screws reduce security and can stress the handle.

- Use the correct screws: Fit the recommended length and grade of screw for the frame material; for timber, screws should bite well into the sash; for aluminium or PVC, use appropriate anchors or bosses.

- Ensure full spindle engagement: Insert the spindle so it fully engages the gear in the lock case; test operation through the full travel to confirm no slop or binding.

- Pack if necessary: If the handle sits proud or the backplate does not sit flat, use appropriate packing washers supplied by the manufacturer to avoid canting the handle.

- Secure cylinder protection: Where a euro cylinder sits in the handle, fit anti-snap escutcheons or cylinder guards to protect against forced entry.

- Torque setting: Tighten fixation screws to manufacturer torque recommendations; over-tightening can crack frames and under-tightening permits rotation under load.

Testing standards and certification to consider

When supplying or recommending offset window handles, reference to recognised standards gives confidence to tradespeople and clients:

- PAS 24: Frames and doors that pass this standard resist a range of forced-entry techniques; handles used on such windows should not be the weak link.

- BS EN 1670: Corrosion resistance testing; important for coastal locations where a handle with low corrosion resistance will degrade quickly.

- BS EN 13126-3: Specific requirements and test methods for durability and strength of window handles; selecting handles tested to this standard ensures mechanical performance.

- Secured by Design: Approved products are independently tested and recommended by police crime prevention specialists; where available choose products with this endorsement.

Maintenance and practical tips for trades and DIY

Regular maintenance extends the life and security of an offset window handle:

- Inspect annually: Check fixings, backplate integrity, and smoothness of operation; address any play immediately.

- Lubricate moving parts: Use a light spray lubricant on the spindle and handle mechanism; avoid heavy grease that attracts dust.

- Replace worn components: If the handle shows signs of wear or the key action becomes stiff, replace the handle or cylinder rather than tolerating reduced security.

- Record specifications: On multi-property jobs, log spindle lengths, offsets and screw types to speed future maintenance or replacements.

Conclusion: Choosing the right offset window handle involves more than appearance; it is about matching the handle to the lock case, ensuring secure fixings, and selecting features such as key-locking, reinforced backplates and cylinder protection. Tradespeople should specify handles tested to recognised standards and follow best-practice installation and maintenance to deliver a secure, long-lasting result. For DIY enthusiasts, understanding the interaction between the offset window handle, spindle, and multipoint system helps avoid common mistakes and keeps homes safe.

Related Reading

Explore more guides on related topics:

Recommended Products

Based on this article, you may find these products helpful:

Part of our guide:

Complete Guide to Window HandlesRelated articles

How to Replace Window Handles for uPVC Windows: Step-by-Step

Replacing worn or broken handles on uPVC windows is a straightforward task that saves money and restores security and smooth operation. This guide explains...

uPVC White Window Handles: Durability and Finish Quality

uPVC white window handles are a common choice for modern homes and trade projects, offering a balance of affordability, corrosion resistance and a neat aes...

How to Replace Window Handles for uPVC Windows: FAQs

Replacing a window handle on uPVC windows is a common maintenance task that prolongs the life of the window and restores secure, smooth operation. This gui...