Universal Window Handles: Do They Actually Fit Most Windows

Guide to window handles

Introduction

Window handles are a small but essential component of any window system. The right window handles improve usability, security and appearance. This guide explains the main types of window handles, how to choose the correct one, and practical steps for measuring, fitting and maintaining them.

Why the right window handles matter

Good window handles provide smooth operation, reliable locking, and a finish that suits the room. Poor-quality handles can cause drafts, stickiness, or compromised security. When replacing or upgrading handles, consider compatibility with existing hardware, the type of window and the locking mechanism.

Common types of window handles

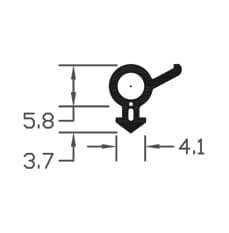

Cockspur handles

Cockspur window handles are surface-mounted and are common on older UPVC and aluminium casement windows. They are simple to fit and use but offer less security than multipoint locking systems. See TSS Cockspur Window Handles for a common option ( /p/tss-cockspur-window-handles ).

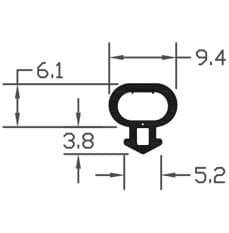

Espagnolette and espag handles

Espag handles operate an internal espagnolette mechanism and are widely used on modern UPVC and aluminium casement windows. Avocet Slimline Offset Window Espag is an example designed for a slim profile ( /p/avocet-slimline-offset-window-espag ). These handles latch into a multiplier mechanism and are generally compatible with euro-profile cylinders.

Offset UPVC handles

Offset handles are designed to clear beads or clip-on cills and provide a neater appearance on UPVC windows. TSS Offset UPVC Window Handles are developed specifically for these applications ( /p/tss-offset-upvc-window-handles ).

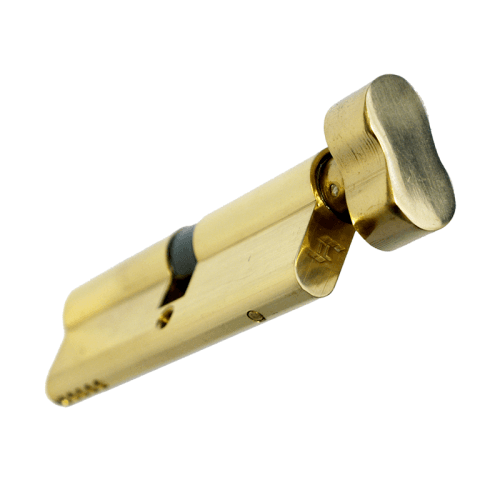

Thumb-turn and key-locking handles

Thumb-turn handles have an internal turn for quick locking from the inside. For added security, use a euro cylinder with thumb-turn function such as the TL Thumb Turn Euro Cylinder ( /p/tl-thumb-turn-euro-cylinder ). Where external key access is required, consider kitemarked cylinders like the Ultion Plus TS007 for enhanced protection ( /p/ultion-plus-ts007-3-kitemarked-euro-key-turn-cylinder ).

Specialised handles for top-hung and in-line mechanisms

Top-hung windows and windows with non-standard opening mechanisms need specific hardware. For top-hung windows you may pair handles with a Top-Hung Window Hinge - Standard ( /p/top-hung-hinge-standard ) or use an In-Line Window Mechanism for a coordinated system ( /p/inline-window-mechanism ).

How to choose the right window handles

Measuring for replacement window handles: step-by-step

Fitting window handles: basic instructions

Note: if you are unsure about compatibility or security, consult a professional. These are general steps for typical UPVC and timber casement handles.

Upgrading security with cylinders and hardware

If you are fitting locking handles, select a certified euro cylinder. Use anti-snap, anti-drill cylinders where security is a priority. The Ultion Plus TS007 3* Kitemarked Euro Key & Turn Cylinder is suitable where high security and insurance compliance are required ( /p/ultion-plus-ts007-3-kitemarked-euro-key-turn-cylinder ).

Fit a thumb-turn cylinder if you need quick internal locking without a key: TL Thumb Turn Euro Cylinder ( /p/tl-thumb-turn-euro-cylinder ). Combine with secure handles that have anti-tamper fixings.

Maintaining window handles and associated hardware

Troubleshooting common problems

Choosing complementary hardware

When replacing handles, consider whether other components need renewal. A worn hinge or mechanism may reduce handle life. Flag Door Hinge in stainless steel is a durable option where hinge replacement is needed ( /p/flag-door-hinge-sss ). Using matched hardware ensures smooth operation and a consistent finish.

Final checklist before purchase

Related Reading

Explore more guides on related topics:

Conclusion

Selecting the right window handles combines compatibility, security and finish. Accurate measurement, correct matching to the locking mechanism and periodic maintenance will extend their life and ensure reliable operation. For many common situations there are direct replacement handles and compatible parts such as TSS Cockspur Window Handles, Avocet Slimline Offset Window Espag, and secure cylinders like Ultion Plus (see product links above). If you are unsure at any stage, a professional installer can confirm the correct specification and fit the hardware safely.

Part of our guide:

Complete Guide to Window HandlesProducts mentioned in this article

Related articles

How to Replace Window Handles for uPVC Windows: Step-by-Step

Replacing worn or broken handles on uPVC windows is a straightforward task that saves money and restores security and smooth operation. This guide explains...

uPVC White Window Handles: Durability and Finish Quality

uPVC white window handles are a common choice for modern homes and trade projects, offering a balance of affordability, corrosion resistance and a neat aes...

How to Replace Window Handles for uPVC Windows: FAQs

Replacing a window handle on uPVC windows is a common maintenance task that prolongs the life of the window and restores secure, smooth operation. This gui...